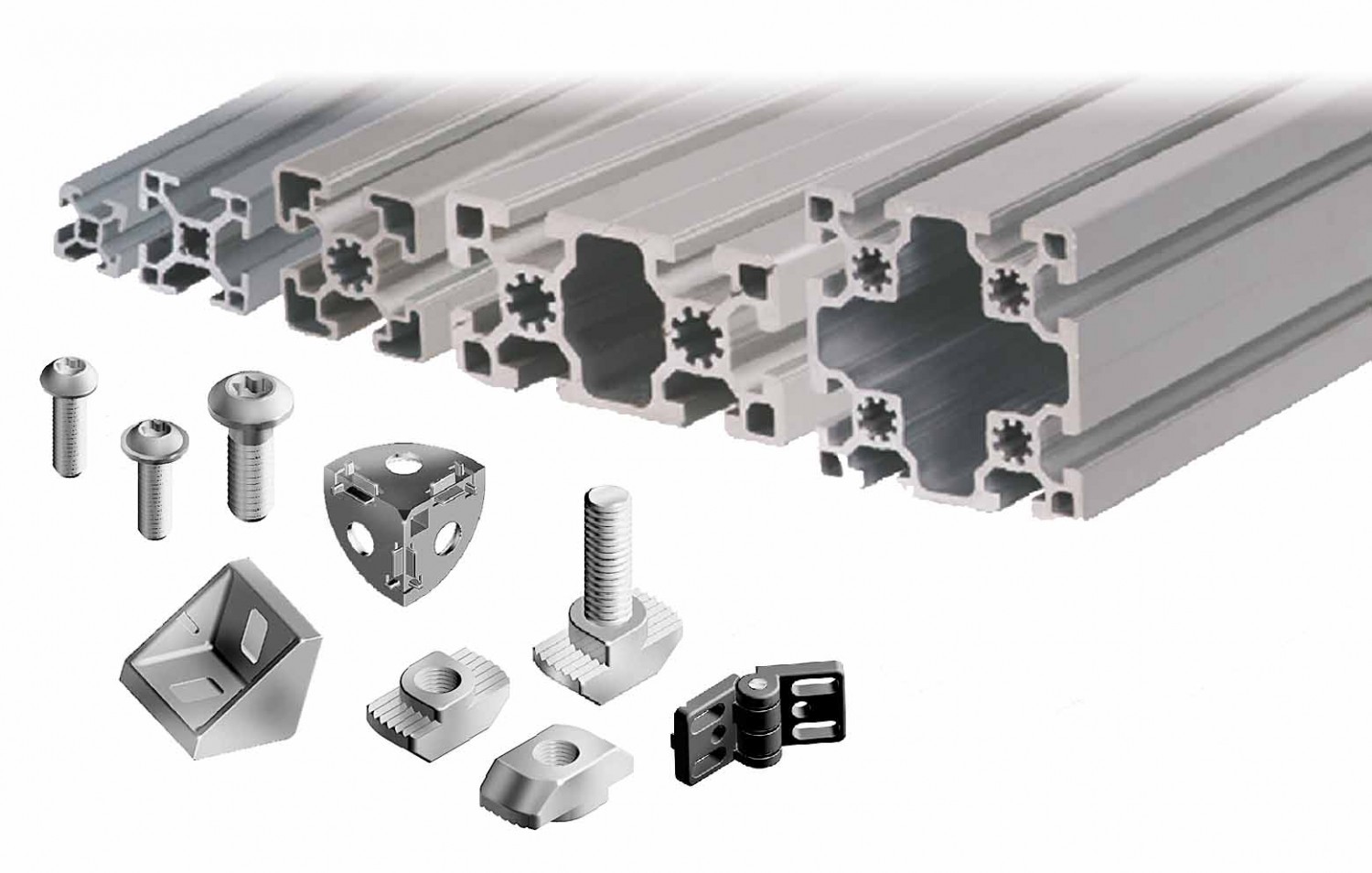

Grade

3003, 5052, 6061 & 7075 I ISO Certified I Square I Rectangular I Upto 6m

Length I Anodized I Sand Blasted I 45x45 (4 Slots), 45x90 (6 Slots), 45x135 (8

Slots) I Mass (Kg/m): 4 Slots = 1.73, 6 Slots = 3.09 and 8 Slots = 4.43

Quick Details:

Affordable Construction Material for African and European Countries

Cladded Valves

Microbots: Small is More

TMT Steel Bars: The Backbone of Modern Construction