Quick Details

Standard: ISO/ISI certified

Quantity: As per Design and Specification

Brand Name: No

Application: Building

Processing Service: Bending, Welding, Cutting and Punching

Packing: Standard Export Package by Bundles or Customised

Lead Time : 21 days to be negotiated

Quantity is in (MT) Metric Ton

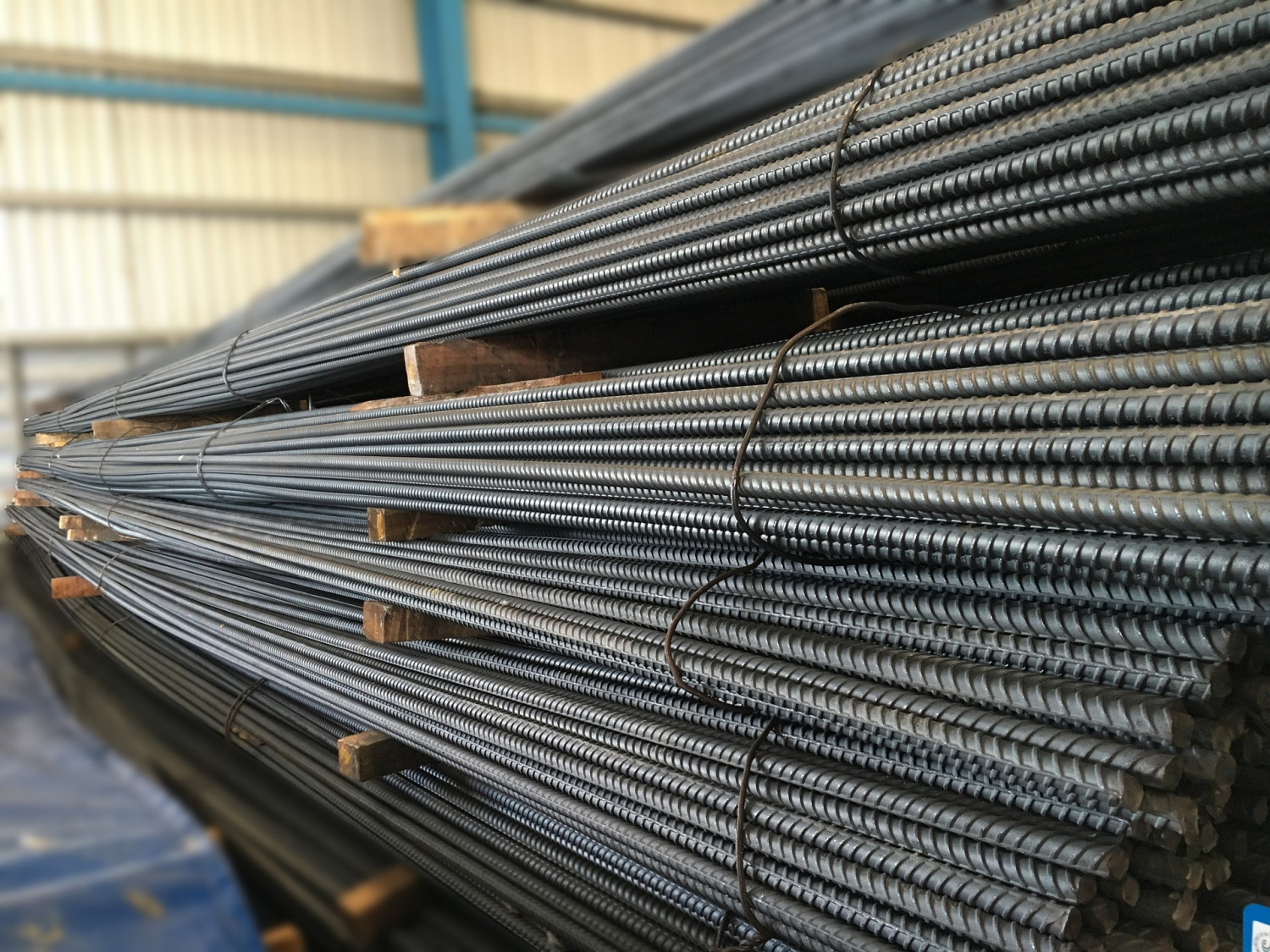

TMT steel bars have emerged as the go-to choice for construction projects, offering unparalleled strength, versatility, and quality assurance. This web page provides valuable insights into TMT steel bars, highlighting their key features, applications, and the stringent quality measures that ensure their superior performance. Whether you're building residential structures, bridges, or industrial complexes, TMT steel bars are the epitome of reliability, making them the preferred choice in the construction industry.

Affordable Construction Material for African and European Countries

Cladded Valves

Microbots: Small is More

TMT Steel Bars: The Backbone of Modern Construction

TMT stands for Thermo-Mechanically Treated, referring to the advanced process that enhances the strength and durability of steel bars.

TMT bars undergo a special heat treatment process, making them stronger, more ductile, and corrosion-resistant compared to regular mild steel bars.

Fe-500 grade TMT bars are most commonly used for residential and commercial construction due to their balanced strength and flexibility.

Yes, earthquake-resistant TMT bars have high elongation properties, making them ideal for seismic zones.

Yes, TMT bars can withstand high temperatures up to 600°C, making them fire-resistant and ideal for fire-prone areas.

CRS (Corrosion-Resistant Steel) TMT bars are designed to resist corrosion, making them suitable for coastal, marine, and humid environments.

TMT bars provide high tensile strength, better bonding with concrete, and resistance to environmental factors, ensuring long-lasting structures.

Yes, TMT bars are recyclable and produced using energy-efficient methods, reducing their environmental impact.